measuring anodize thickness|anodize thickness chart : makers Units. It is important to be consistent in the use of units – failure to do so can have disastrous consequences!. The SI unit of measurement used for coating thickness in the majority of standards, throughout our website and on any documentation we produce, is the micrometre or micron (µm) which is one-thousandth of a millimetre.. Older (outdated) engineering drawings .

webPágina · Serviços funerários e cemitério. +55 51 3715-3868. Funerária Halmenschlager Santa Cruz do Sul, Santa Cruz do Sul. 1.353 curtidas · 4 falando sobre isso · 1 esteve aqui.

{plog:ftitle_list}

Resultado da 14 de jun. de 2023 · Télécharger - 60 Seconds! (60 Seconds!) 2019: Une comédie noire captivante. 60 Seconds ! est un jeu de survie captivant dans le genre comé . 60 .

ASTM B244-09(2021) ‒ Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals .The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . DeFelsko manufactures a hand-held, non . Significance and Use 5.1 The thickness of a coating is often critical to its performance. This eddy-current method is nondestructive and is suitable for measuring the thickness of anodic coatings on aluminum, as well as the thickness of most nonconductive

Yarn Cotton Moisture Meter factories

The 6000AN Series Anodizing Coating Thickness Gauge is a versatile, rugged tester using eddy current principles to measure coating thickness on non-ferrous metals, accurately and quickly. Measures Non-Magnetic Coatings .Type III Anodize Thickness Guide. Alloy. Major Constituent(in) Maximum Thickness* Color Overtones*** 1100. 99.5% pure Alum..003. Gray/Green** 2011. Copper. Not recommended . Not recommended . 2014. . It is the mission of the Aluminum Anodizers Council to support its members -- and users of anodized aluminum -- through education, advocacy, and .Units. It is important to be consistent in the use of units – failure to do so can have disastrous consequences!. The SI unit of measurement used for coating thickness in the majority of standards, throughout our website and on any documentation we produce, is the micrometre or micron (µm) which is one-thousandth of a millimetre.. Older (outdated) engineering drawings .The thickness of the anodic plating plays a critical role in products from consumer goods, aerospace parts, and automotive chassis. Meeting industry specifications such as MIL-A 8265 Type III require accurate and precise measurement of anodized aluminum thicknesses. The measuring instruments shown below provide just such accuracy.

Thickness measurement is a crucial aspect of quality control in anodizing. The thickness of the anodic oxide layer directly influences its protective properties and durability. The most common method for measuring the thickness of anodic coatings is the eddy current NDT method, as specified in ASTM B244.

Anodized aluminum and titanium are rapidly becoming the materials of choice for many new products within aerospace, automotive, medical, and other industrial markets . Ability to measure film thickness with minimal influence of surface reflectance, intensity fluctuations and distance from the sample;Ultrasonic coating thickness gages (e.g. PosiTector 200) emit a high frequency sound pulse that travels into the coating via a coupling gel and reflects from ANY surface that is different in density.Paint thickness readings are obtained by measuring the time taken for the ultrasonic signal to propagate from the probe to the coating/substrate interface and back.Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. . Application examples: Anodizing on aluminum; paint, lacquer or plastic on aluminum or .

When we anodize aluminum, we create a protective and decorative surface layer. It's important to measure the thickness of this layer to ensure that it meets . Hard Coat Anodizing. Regular Anodizing. Process. Performed at lower temperatures and higher current densities, resulting in a harder and thicker layer. Conducted at room temperature with lower current densities, producing a thinner and somewhat softer layer. Oxide Layer Thickness. Typically, the thickness ranges from 0.002 to 0.0045 inches .Measuring plating thickness is an essential part of product development in dozens of industries. PlatingThickness.com – Your source for measuring instruments in plating industry +1 860 683-0781Hardcoat thickness is typically 0.002" (0.0508 mm). Half the coating thickness is build-up and half is penetration into the base metal. For the threaded rod on the right, the diameter increased by 0.002" since half of the coating thickness (0.001") built up the diameter on each side of the rod. Hardcoat Blind Holes or Through Holes

Eddy current techniques are used to nondestructively measure the thickness of nonconductive coatings on nonferrous metal substrates. A coil of fine wire conducting a high-frequency alternating current (above 1 MHz) is .

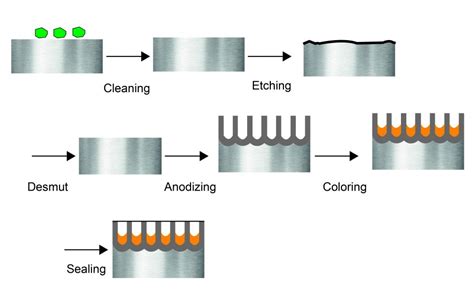

Anodizing is used to increase the thickness of the natural oxide layer on the surface of metal parts, to increase resistance to corrosion and wear, and to provide better adhesion for paint primers and glues. . Solutions that measure . Anodizing is a process that is used to increase the thickness of the natural oxide layer on the surface of aluminum parts. Measuring the thickness of the ano.A thickness meter is an essential quality assurance tool when anodizing, galvanizing and applying zinc coating to metallic surfaces. A thickness meter also is used to measure body paint thickness and uniformity on pre-owned cars, revealing repainted spots, identifying hidden damages and exposing undisclosed accidents. . PCE-CT 5000H is a .

Figure 1 - NAS Measurement of Anodizing When measuring small or hard-to-reach areas, the PosiTector N Microprobes are an ideal measurement alternative. With probe tips of either 0°, 45° or 90° readings can be taken in deep holes, on small ledges or on inside diameters. When a fixture or quick release adapter is used, N microprobes have .

Common applications for eddy-current coating thickness measurement include liquid or powder coating over aluminum and non-magnetic stainless steel as well as anodize over aluminum. Selecting A Gage Many instruments available today combine both magnetic induction and eddy-current methods.In general terms, for Type III anodize ½ of the coating thickness penetrates into the surface of the parts while the other 1/2 builds up on the surface. Thus for a typical 0.002” thickness requirement, there is 0.001” dimensional change per surface. For any new parts, Anoplate makes sure that the required specifications are included in the .

Aluminum anodizing represents a prevalent surface finishing technique employed for machined parts. With various types of anodization available, we will delve into Type III anodizing. This discussion will encompass its definition, specifications certification, achievable thickness, hardness, colors, applicable materials, process, benefits, and a comparison .depending on the anodized thickness desired. 4. TOLERANCE — Precise control can normally be maintained on thickness. Coating thickness can range from .0005" to .0035" as specified. (This is the combined surface and penetration ± 10% of the total thickness, but not less than ± .0001". Tighter tolerances may be possibleThe above publication goes on to call out the designations of other more specific coatings and methods of pretreatment of the aluminum prior to anodizing. Coating thickness can be measured by an "eddy current," nondestructive test instrument as per ASTM B 244-79, or by cutting a cross-section of the anodized aluminum, mounting it in a slide . The anodizing efficiency is estimated to be 90%, and the current density is 2 A/cm². What will be the thickness of the anodic coating? Anodic Coating Thickness (μm) = (12 V × 30 minutes) / (2.04 × 0.90 × 2 A/cm²) Calculating this equation yields the anodic coating thickness in micrometers.

Coating Thickness Measurement: Methods such as eddy current testing and cross-sectional microscopy are used. Adhesion Testing: Adhesion of the anodized layer is tested using methods like tape tests or bend tests. . Anodized aluminum can be dyed in a wide range of colors. This is achieved by incorporating organic or inorganic dyes into the .Eddy current thickness testing meters are usually used to measure the anodized (oxide) layer. This will measure coating thickness, but not build-up. Build-up must be measured by comparing a finished part to . thickness of the anodizing! The coating of these parts ranges from .0003” on the left to greater than .002” on the right- all are .

Portable Grain Moisture Meter factories

typical anodizing thickness

Grain Moisture Meter (LDS-1G) factories

how to measure anodize thickness

how to check anodizing thickness

Resultado da Alerta sobre risco à saúde. Salmeterol é um agonista beta-2 adrenérgico de longa ação utilizada no tratamento da asma e da doença pulmonar obstrutiva crônica. [ 1]

measuring anodize thickness|anodize thickness chart